TYPES OF ZINC-FLAKE COATINGS

There are a few main players that specialize in the production of solvent-based zinc-flake coatings. In the United States, if a zinc-flake coating is called out on a part print, the majority of time either a coating system is an approved coating choice.

Zinc flake coating is a coating of zinc and aluminum flakes that is applied to protect against corrosion.

The zinc flake coating protects the underlying metal from environmental influences. Zinc flake coating is applied with state-of-the-art coating techniques, such as dip-spin, rack dip-spin or fully automated spray processes.

Zinc flake coatings are applied using state-of-the-art dip-spin, dip coating or fully automated wet coating processes. As license holder of the leading suppliers, It’s a NG Coaters can offer these processes at its global facilities.

Fields of use of zinc flake coating:

It is used primarily in the automotive industry and wherever excellent corrosion protection combined with other functional and decorative properties is paramount. NG Coaters fulfills the entire set of specifications of the international automobile manufacturers.

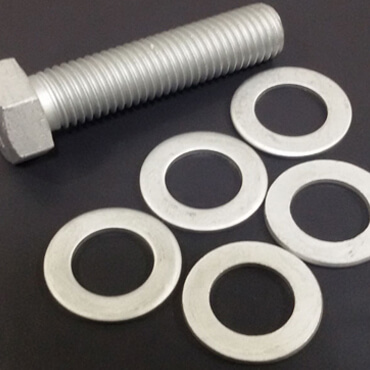

- Fastening elements

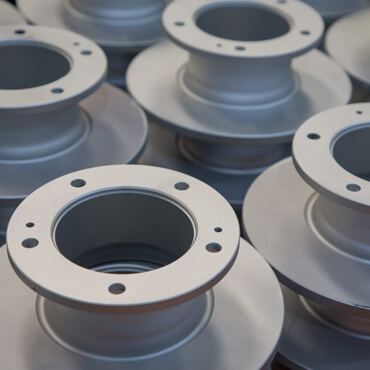

- Brake components

- Chassis components

- Springs

- Threaded parts

- Punched parts

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

anamika_ngcoaters

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

anamika_ngcoaters2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

anamika_ngcoaters

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

anamika_ngcoaters2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai