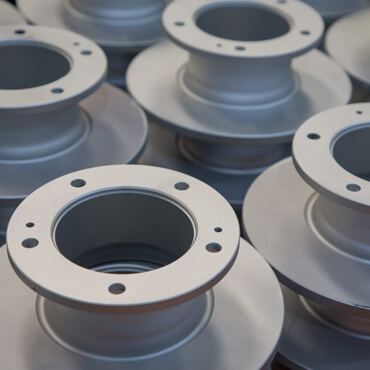

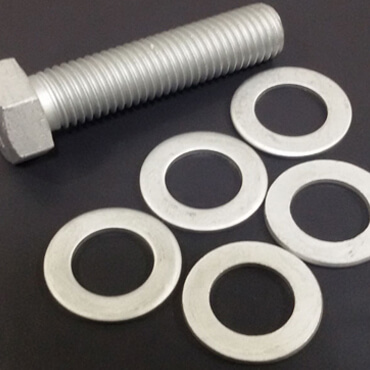

Zinc Flake Coating

We are engaged in presenting an extensive range of Zinc Flake Coating to our clients. In addition to this, customers can avail these plants at competitive prices.

Zinc Aluminium Flake Coating

We are the leading organization to offer our precious clients an optimum quality Zinc Aluminum Flake Coating Service. This service is carried out under the strict supervision of our experts using the best grade tools and advanced techniques.

Non-Electrolytically Applied Zinc Flake Coating

Our team of experts use highest quality chemicals to apply the Non-Electrolytically Applied Zinc Flake Coating. It is more effective way for ensuring corrosion protection in comparison to the electrolytically deposited zinc or zinc alloys.

PTFE Coating

PTFE Coating are used in various applications like automatic power factor correction, and group fixed power factor correction, etc. The coating on the trays ensures that the heating is even and the product does not get overheated.

Polytetrafluoroethylene Coating

Polytetrafluoroethylene PTFE coating uses a two-coat (primer/topcoat) system. These products have the highest operating temperature of any fluoropolymer and have extremely low coefficient of friction, fair abrasion resistance and good chemical resistance.

Shot Blasting Facility

We have the latest shot blasting machine with automated controls which can provide uniform shot blasting with consistency from batch to batch. We can provide shot blasting to meet the requirements with the specified shot size.

Baking Furnace

The baking furnace is used for Zinc flake coatings and other thermosetting coatings for improved wear and corrosion protection.

Dip Spin Coating Facility

We have the state of art dip spin coating facility combined with baking furnace. The output of dip spin facility is 200 Kg per hour The dipspin coater is PLC controlled with programmable sequencing steps to provide uniform coating thickness consistently on all intricate surfaces of the component.